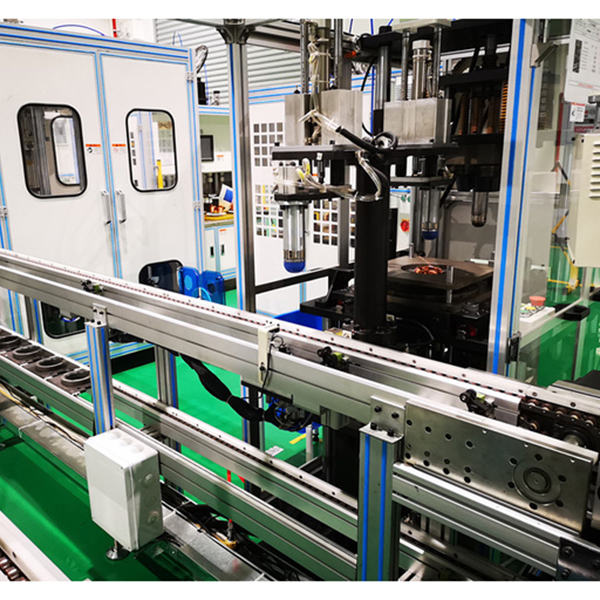

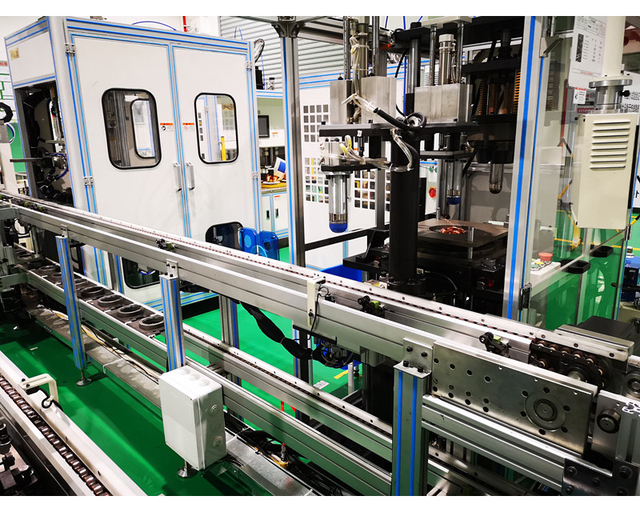

Mohala oa tlhahiso ea othomathike oa Stator (mokhoa oa ketane ea lebelo habeli 2)

Tlhaloso ea Sehlahisoa

Mohala oa tlhahiso ea othomathike o fetisetsa lisebelisoa ka mohala oa kopano oa ketane ea lebelo le habeli, (ho kenyeletsoa ho kenngoa ha pampiri, ho tsoelipana, ho kenya, ho theha lipakeng, ho tlama, ho qeta le lits'ebetso tse ling) ka mokhoa o nepahetseng le ts'ebetso e tsitsitseng le e tšepahalang.

Sebopeho

Mokhoa oa ho fetola mochini oa tjheseletsa oa mochini oa rotor o iketsang line letheba?

Rotor othomathike line spot welder qalong e ne e e-na le AC controller le AC spot welder, empa hona joale ho sa tsitsang ha AC spot welder le bothata ba ho tjheseletsa ho ile ha etsa hore e nkeloe sebaka ke molaoli oa DC inverter frequency, intermediate frequency inverter, le spot welder. Sehloohong sena, re tla tšohla mekhoa e fapaneng ea ho lokisa boemo ba hona joale ba rotor automatic wire spot welder:

1. Taolo ea matla a kamehla: Ho sebelisa mokhoa o tsitsitseng oa matla Q=UI e ka qoba ho phahama ha motlakase oa motlakase le mocheso ha o sebelisa mokhoa o sa khaotseng oa hona joale, le ho thibela mocheso oa Q = I2Rt hore o se ke oa phahama. Ka ho sebelisa mokhoa o itseng oa matla Q=UI, mocheso o ka leka-lekana.

2. Tekanyo ea motlakase ea li-rotor tse peli tse itekanetseng: tekanyo ea motlakase e lokela ho etsoa haufi le lipalo tse ntle le tse mpe ka hohle kamoo ho ka khonehang. Taba ke ho laola boleng ba motlakase pakeng tsa lipalo tse ntle le tse mpe, eseng motlakase oa potoloho eohle.

3. Fetola ho tloha ho 1-pulse discharge ho ea ho 2-pulse discharge kapa 3-pulse discharge (nako eohle ea ho qeta nako e ntse e sa fetohe), le ho fokotsa matla a matla (kapa boleng ba hona joale) ho ea bonyane. Haeba ho sebelisoa pulsed discharge, boleng ba matla bo tla hloka ho eketseha ho fihlela mocheso o lakatsehang oa welding. Haeba ho sebelisoa phepelo ea makhetlo a mabeli (tekanyo ea pele ea ho ntša pulse e behoa tlaase, 'me boleng ba bobeli ba ho tsoa ha pulse bo behiloe holimo), boleng ba matla (kapa boleng ba hona joale) bo ka fokotsoa haholo bakeng sa welding. Ho fokotseha ha boleng ba matla (kapa boleng ba hona joale) ho fella ka ho fokotseha ha ho apara ha li-electrode le botsitso bo ntlafetseng ba welding. Q=I2Rt e bolela hore ho bokellana ha mocheso ho ameha haholo ke keketseho ea boleng ba hona joale. Ka hona, ha u beha li-parameter, fokotsa boleng ba hona joale (kapa boleng ba matla) ho bonyane.

4. Kenya sebaka sa tungsten electrode ka hook tlas'a letheba tjheseletsa ka eleketrode mpe, hobane hona joale e phallang ho tloha hokong ho eleketrode tungsten, ho baka "elektrone mokhatlo oa", ho fella ka ka tlaase ho moo liathomo tsa tšepe phallang ho eleketrode, etsa hore e silafetseng le e khathetse. "Motsamao oa elektronike" o bolela hore ho phalla ha lielektrone tsa valence tsa tšepe ho baka motsamao oa 'mele oa mokelikeli o nang le liathomo tsa tšepe.

Ho ea ka mokhoa o ka holimo, phetoho ea hona joale ea mochine oa welding oa rotor o ikemetseng o ka phethoa ka katleho. Sengoliloeng sena se ikemiselitse ho utloisisa hamolemo ts'ebeliso ea li-electromechanical tsa rotor automatic wire spot welders ho ntlafatsa katleho ea tlhahiso le ho boloka matla. Ho phaella moo, tlhokomelo ea kamehla e lokela ho kenngoa ts'ebetsong ea melapo ea tlhahiso ea rotor e ikemetseng. Sena se thusa ho phela nako e telele le ho nepahala ha ts'ebetso.